SPT4412LV-320 300 degree big angle support pulse width feedback remote control car servo

Brand:

SPT Servo

Potentiometer:

Mechanics

Motor:

Core

Voltage Range:

4.8V/6.0V

Neutral Point:

1500μs

Signal Frequency:

330Hz

PWM Voltage:

3.3V-5.0V

PWM Voltage:

3.3V-5.0V

Feedback Angle:

Yes

Operating Temperature:

-10℃-50℃

Cycle:

20ms

Dead band:

4μs

Default Direction:

CCW

Yes / no Lock:

Lock

Remote control Angle:

150°

500-2500μs Angle:

300° / PWM

Quiescent Current:

50mAh

Rated Current:

1.0A

Blocking Current:

1.8A

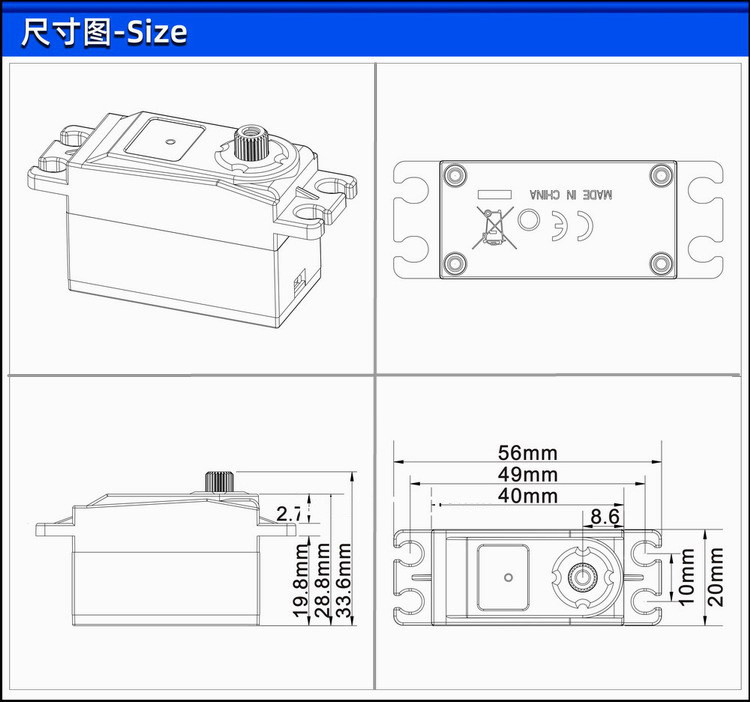

Weight / Dimensions:

50g / 40*20*28.3mm

Output Gear:

Futaba 25T

Gear Material:

All Metal Gear

Shell Material:

Half Aluminum Shell

Bearing:

2BB

Connector Wire Length:

260MM

line Definition:

Brown-/Red+/Orange s

Operating Speed:

4.8V/0.11''/60°

6.0V/0.09''/60°

/

Stall Torque:

4.8V/10kg.cm

6.0V/12kg.cm

/

Angle range: the default of the remote control is 150 degrees, and the maximum is 180 degrees; Support the control board 0.5-2.5ms, the maximum angle is 300 degrees, and support pulse width feedback.

Voltage and current: the supporting voltage of the Servo is between 4.8v-6.0v, and the BEC is at least 1.5A or above.

The circuit functions: this servo has soft start and load blocking protection (10s continuous load blocking, current of 2.0A or above) With lock (if the remote control is ignored, the control board control needs to send a command, even if the disconnection signal is always executed, and the servo has locking force; without lock, the same command needs to be sent continuously, so that the servo can be effectively fixed in one position, and the disconnection signal is that the servo has no locking force) .

Application: remote control vehicle and climbing vehicle; Single chip microcomputer control board

Warm Prompt:

1. The maximum 1cm lever of the servo tested torque. It can not be used under full load in actual use. The motor of any servo will be heated greatly under the load, resulting in easy burnout. We recommend to use the best torque within 1 / 2 or less of the nominal maximum torque. During use, you can observe the current or temperature of the servo. If the current is too high or the temperature of the servo itself is high, there may be full load or overload. Try to leave margin to maximize the service life of the servo.

2. The servo test includes soft start function, Blockage protection function (if the load is blocked continuously for 10 seconds, the current will also drop, and the servo has no force, it will recover after eliminating the blocked load), three wire angle feedback function, and adjustment for the spark of motor carbon brush.

3. The pulse width of the control board is 500us-2500us, the angle is about 200 degrees, the default angle of the remote controller is 100 degrees, and the maximum fine-tuning angle of the remote controller is about 138 degrees (There with small difference because of use different remote controllers)

4. The power supply current of the servo must be higher than 1A, then the servo can work normally. The faster the reverse speed is, the higher the instantaneous current will be.

Three wires angle feedback of the servo

The servo is controlled by the duty cycle of 500-2500us. Angle feedback is actually an inverse process. After receiving the controller signal, the servo sends back a 500-2500 signal to the main control.

For ordinary servo, the signal wire is always in the input state. The state of this servo signal wire with feedback is switched. After receiving 500-2500us signal 100US, it is switched to output, and then switched to input after transmitting the angle position. The advantage of this feedback method is that the wiring is simple and the feedback angle is accurate. When the servo is controlled at 1500us position, 1500us is sent back It is more accurate and easier than the four wire detection potentiometer ADC.