360 Continuous Rotation SPT4412LV-360 Linear change industrial robot servo

Brand:

SPT Servo

Potentiometer:

Mechanics

Motor:

Core

Voltage Range:

4.8V/6.0V

Neutral Point:

1500μs

Signal Frequency:

330Hz

PWM Voltage:

3.3V-5.0V

PWM Voltage:

3.3V-5.0V

Feedback Angle:

No

Operating Temperature:

-10℃-50℃

Cycle:

20ms

Dead band:

4μs

Default Direction:

CCW

Yes / no Lock:

Lock

Remote control Angle:

Continuous Rotation°

500-2500μs Angle:

Linear Change/° / PWM

Quiescent Current:

50mAh

Rated Current:

1.0A

Blocking Current:

1.8A

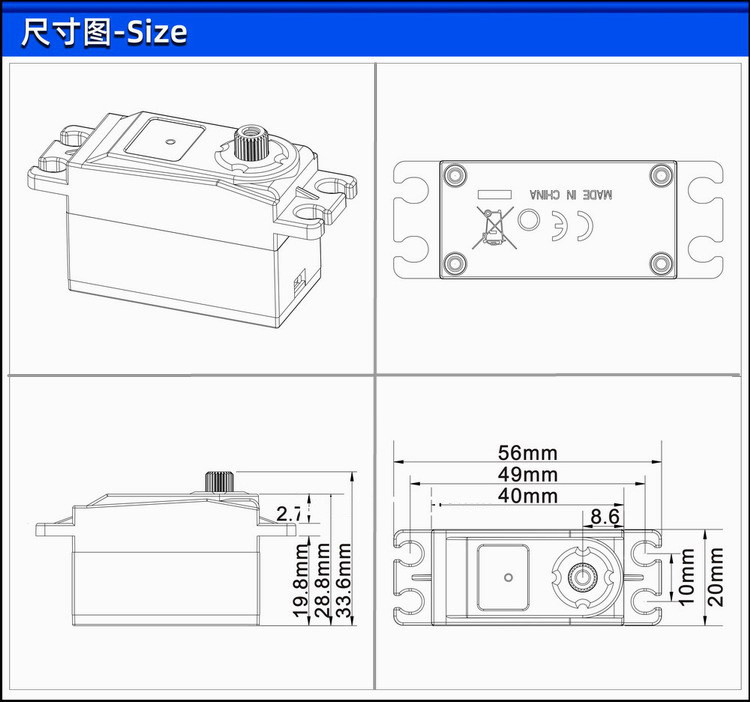

Weight / Dimensions:

50g / 40*20*28.3mm

Output Gear:

Futaba 25T

Gear Material:

All Metal Gear

Shell Material:

Half Aluminum Shell

Bearing:

2BB

Connector Wire Length:

260MM

line Definition:

Brown-/Red+/Orange s

Operating Speed:

4.8V87rpm

6.0V108rpm

/

Stall Torque:

/

/

/

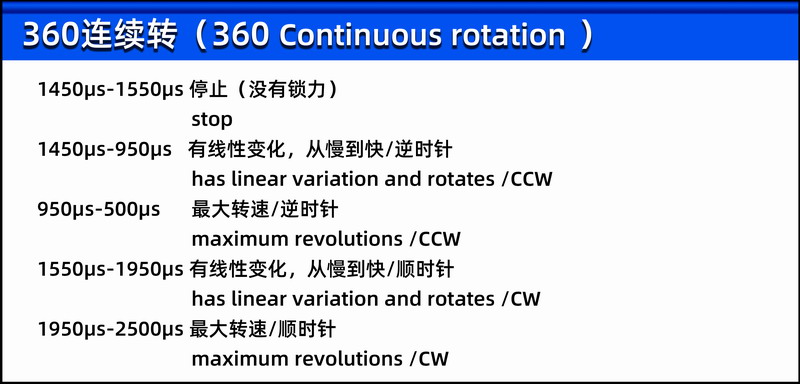

From Dec 1st 2021 change the control pulse width to the following figure, which was 1450-1000 μ S before and 2000-2500 μ S has a linear change!

Three wires angle feedback of the servo

The servo is controlled by the duty cycle of 500-2500us. Angle feedback is actually an inverse process. After receiving the controller signal, the servo sends back a 500-2500 signal to the main control.

For ordinary servo, the signal wire is always in the input state. The state of this servo signal wire with feedback is switched. After receiving 500-2500us signal 100US, it is switched to output, and then switched to input after transmitting the angle position. The advantage of this feedback method is that the wiring is simple and the feedback angle is accurate. When the servo is controlled at 1500us position, 1500us is sent back It is more accurate and easier than the four wire detection potentiometer ADC.